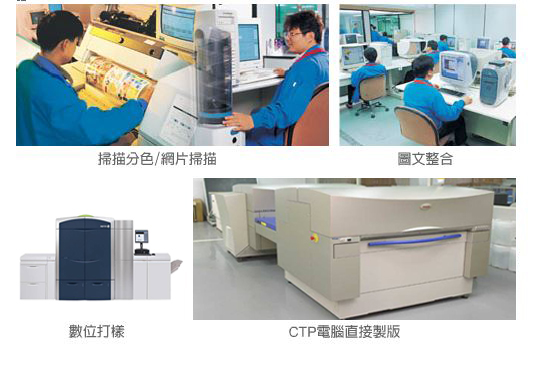

Pre-press process-digitized process

About equipment

| 1. | Input equipment | |

| roller and platform color scanner | 1set | |

| 2. | Plate processing equipment | |

| workstations for Mac and PC text and image plates | 14set | |

| Copy dot screen scanner | 1set | |

| 3. | Output equipment | |

| raster image processors (RIP) | 3set | |

| Screen tanto 6120 | 1set | |

| proofing system (Epson Stylus Pro 9900) | 3set | |

| digital printer (FUJI XEROX COLOR 1000i) | 1set | |

| 4. | Plate burning equipment | |

| Wang Chang W-D-3648A | 1set | |

| 5. | Computer-to-plate (CTP) system | |

| Kodak Magnus 800 Quantum X | 1set | |

| 6. | Quality control system | |

| Heidelberg CPC-32 automatic ink setting system | 1set | |

| Mitsubishi PPC2000 automatic ink setting system | 1set | |

|

Komori PCC automatic ink setting system |

1set | |

| 7. | CMS Color manage system | |

|

Color Manage System Spectrometer -ITISIS PLUS  |

1set | |

Design and editing

We use MAC and PC computer operation to assist customers to design, draft, and edit.

Color separation

Color separation for original script with high resolution and premium quality is proceeded. Delicate and high quality color alteration services are available.Through exporting existing pictures or photos to the output system such as computer peripherals including scanners and digital cameras, images are digitized. Then with image processing software, for example, PhotoShop, PhotoImpact… to add interesting and attractive special effects.

Small plate printing

SHEN’s provides complete images and applications of website processing software for various electronic scripts and production output.

Output operations

SHEN’s offers the most complete collection of PostScript Chinese texts. High speed OPI printing interface replacement and HiFi color output services are also available.

Large plate printing

Via a computer, a large plate can be combined quickly and SHEN’s also provides CTF (Computer to film) or CTP (Computer to plate) services.

Digital proofing

EPSON 9900 advanced digital proofing machine that delivers works with high speed and precision. At the same time, it can shorten the time for modification for quick calibration.

CTP

A complete digital process before press is utilized to shorten work hours via CTP.

CPC32, Mitsubishi PPC2000 and Komori PCC quality control system

By combining integrated relevant ink demanding files for accurate, fast, and reliable printing operation.

CMS and CIP3

Comprehensive color management system and CIP3 printing data control system are utilized.